THERMIC FLUID HEATER

CBL Thermic Fluid Heater stands as an optimal solution amongst the dynamic energy scenario.

THERMIC FLUID HEATER

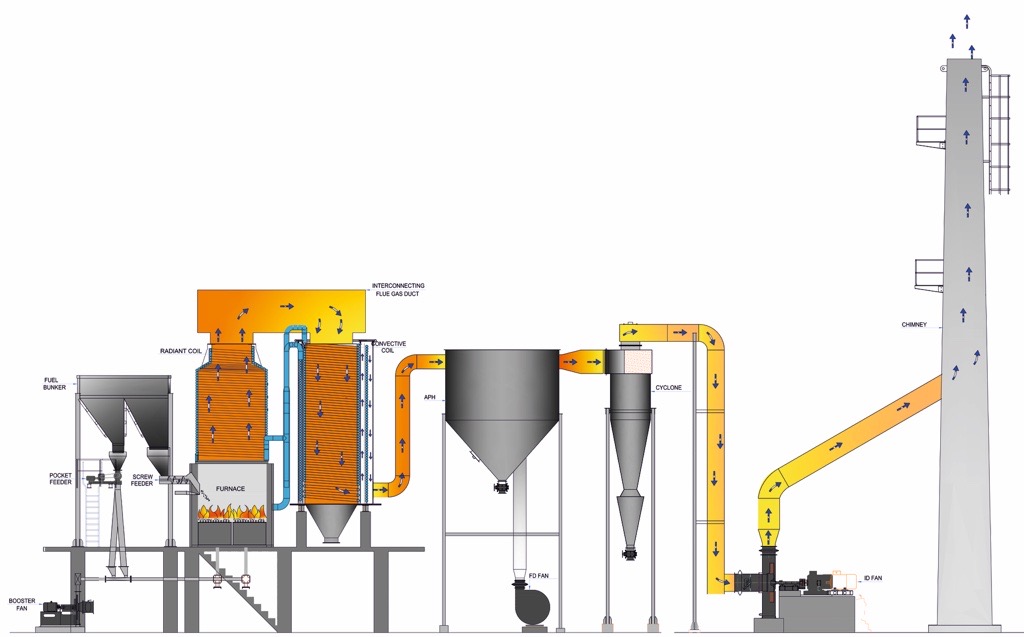

A Thermic Fluid Heater is industrial heating equipment, used where only heat transfers are desired instead of pressure. In this equipment, a thermic fluid is circulated in the entire system for heat transfers to the desired processes. Combustion process heats up the thermic fluid, and this fluid carries and rejects this heat to the desired fluid for concluding the processes. After rejecting it, this fluid comes back again to the thermic fluid heater.

CBL Thermic Fluid Heater stands as an optimal solution amongst the dynamic energy scenario. The vertical design offers compactness across various multi fuel flexibility which makes it an ideal choice for heating applications in Textile, Chemical, Plywood, Food & Beverages, Pharmaceutical, Rubber, Solvent, Edible Oil and all other industries requiring indirect heating.

Unique Design Features

- Furnace design suitable for low grade fuels.

- Minimum exposed surface reducing radiation/convective losses.

- Large feeding door for ease of feeding.

- Large furnace volume for efficient combustion.

- Air pre-heater improves combustion efficiency and ensures lower power consumption of ID fan.

- Design adopts principles of DIN and API codes.

- Occupies Minimum space and site work.

- Quick and easy installation.

- Safety relief valve to prevent high pressure.

Our Offerings

Reciprocating Grate

- Capacity upto 50M kcal/hr

- Temperature upto 300°C

- Fuel:Riche Husk, Coal, Bagasse, Wood Chips, Mustard Husk, Paddy Straw, Palm Fiber, Briquettes, Pellets

Features

- Suitable for complex and versatile Biomass Fues

- Robust construction with minimum maintenance, resulting in lower life and reliable operations

- High alloy steel air-cooled grate bars

- Efficient combustion due to better air distrubution

- The sloped air-cooled reciprocating grate appears inclined ladder shape that make the fuel move towards ash discharge end easily

AFBC

- Capacity upto 50M kcal/hr

- Temperature upto 300°C

- Fuel: Rice, Husk, Coal

Features

- High efficiency

- Fast response to load fluctuations.

- High Reliability (Reduce Maintenance Cost)

- Flexibiilty on versatile fuels

- Maximum Fuel & Auxillery power saving

- Simple Operation & Quick Starup

Plain Grate

- Capacity upto 20M kcal/hr

- Temp upto 300°C

- Fuel: Rice Husk, Coal, Bagasse, Wood Chips, Musturd Husk, Briquettes

Features

- SWIRLING air injection for better post combustion burning fuels.

- Ability to free moist fuel

- Manual & Auto fuel feeding options

- Highly efficient low speed fans

- Anti abrasive coating in the cyclones

- High Grade Cast Iron Fire Doors

Oil/Gas

- Capacity upto 50M kcal/hr

- Temp upto 300°C

- Fuel: LDO, HSD, NG, PNG

Features

- In the system servo motors are installed for air dampers, fuel regularor and combustion head control to optimize air flow pressure loss in the combustion head. The ratio between fuel, combustion air and air flow is adjusted electronically.

- This system also take cares of burner control and safety functions.

- It can be connected to external system via bus interface (Modbus, Profibus).

- On/Off/step less modulation options are available

- Options for External APH (efficiency upto 92%)

Deaerator Cum Expansion Tank

- It comes with a buffer vessel to prevent cooling of hot oil coming from the process

- The Tangential Thermic Fluid entry in the deaerator ensures optimal deaeration.

- Requires Less Space.