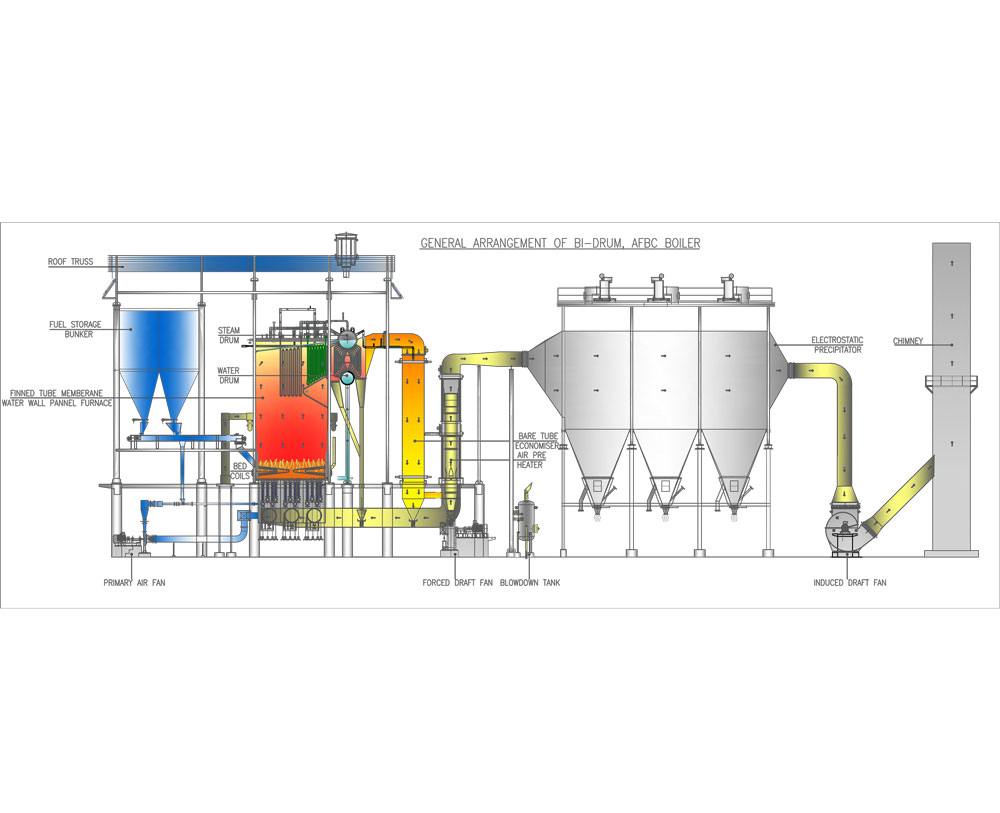

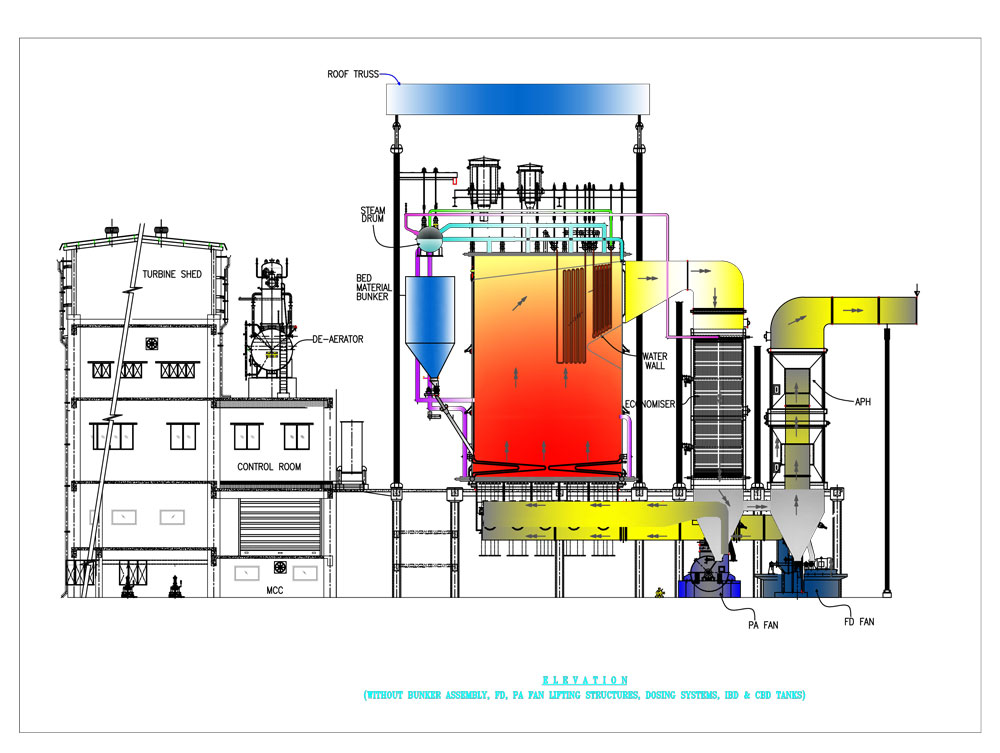

AFBC Boilers

AFBC boilers provide an effective solution for generating heat and power. They burn various types of fuel efficiently, achieving over 85% combustion efficiency, regardless of ash content

Advantages of AFBC Boilers

- High efficiency

- Fast response to load variation/fluctuation

- Low on operating cost

- Simple operation and quick start up

- High reliability

- Flexible on versatile fuels

- Maximum fuel & Auxiallary power saving

- Fuel: Indian /Imported Coal, Lignite, Rice Husk, Washery Rejects, Petcoke, Dolachar

Operating range

Capacity

upto 175 TPH

Pressure

Upto 130 kg/cm²(g)

Temperature

Upto 540°C

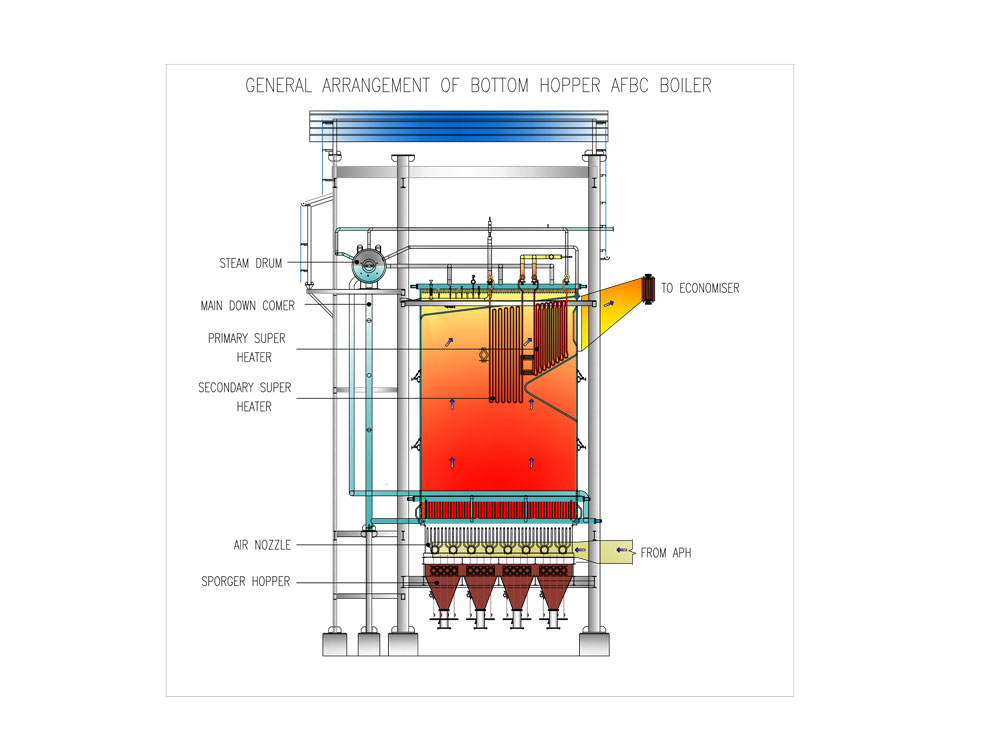

Low Maintenance Design Features for AFBC Boilers

- Water wall membrane type for maximum heat absorption and structural rigidity

- Four stage steam separation to ensure zero carryover

- Optimum velocity and pitch in economizer for better life of tubes

- Studded in-bed evaporator tubes are immersed in the bed to extract heat

- Welded and factory assembled PA and fuel nozzles

- High efficient fans to ensure optimal power consumption and minimum noise level

Hopper Bottom (Fluid Bed) Salient Features

- Reduced maintenance in the furnace as the combustor does not have any moving parts

- Optimum combustion due to uniform temperature distribution in the bed and agitating characteristic of the fluid bed

- Higher efficiency as a result of low excess air requirement

- Lower NOx and CO emissions

- Low SOx emission with limestone addition

- Low-temperature operation minimizes the biomass fuel ash agglomeration and fouling tendency

Continuous slow draining of bedash aids: - Easy settling and disposal of large-sized particles, which hamper fluidization

- Maintaining alkali concentration below acceptable levels

- Avoiding accumulation of denser particles in bed in maintaining uniform bed density across the entire bed

- Under-bed / over-bed fuel feeding for proper distribution of fuel

AFBC: A Versatile Boiler with Effortless Operation and Rapid Startup

- Available in Bi-drum/ Single drum

- Suitable to generate saturated and super heated systems

- Suitable for cogeneration and captive power plants

- Underbed/ Overbed fuel feeding/ Bottom hopper design

- Low excess air requirement resulting in higher efficiency

- A secondary firing system is provided in the furnace to ensure optimal combustion resulting in minimum un-burnt fuel, reduced CO level in the flue gas and improved efficiency