HYPAC

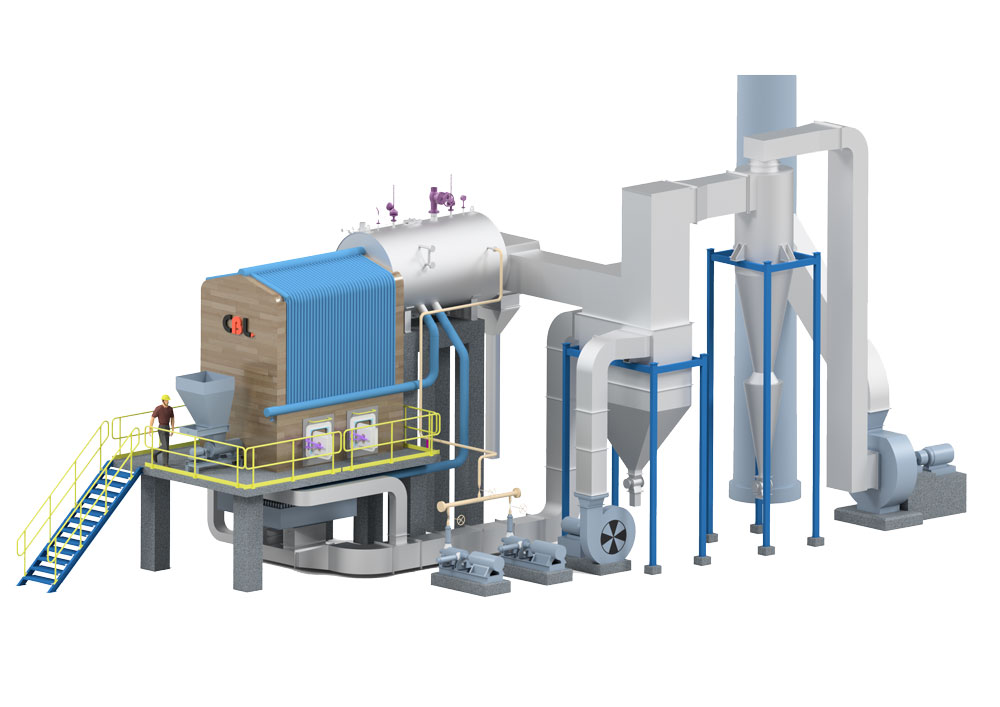

HYPAC from CBL is the most proficient and economical Boiler offering to the industry by combining the benefits of water tube and smoke tube design.

Easy to operate

High thermal efficiency

Low operational cost

Environment friendly

HYPAC – Water – cum – Smoke Tube Boiler

HYPAC has versatile design for use with different fuel types and as a multi-fuel firing unit. Its smoke tube portion has a large water holding capacity along with a large water-steam interface area. This ensures 98% steam dryness inspite of load fluctuations. The extended height in the furnace enhances efficiency and increases longevity.

Operating range

Capacity

up to 25 TPH

Pressure

up to 28kg/ CM²

Fuel

Multiple fuel compatibility

Low fuel consumption

- Minimum heat loss due to membrane type water wall design

- Most efficient combustion with an optimum residence time of flue gases in the furnace.

- Better heat transfer and longer tube life due to optimum velocities in smoke tubes

- Variable frequency fuel feeder (VDF) for complete combustion of fuel

- Swirling air injection for better post-combustion burning of fuel

Reduced maintenance cost

- Highly efficient low-speed fans

- Minimum refractory work

- Reputed brands of Mountings and fittings

- Anti-abrasive filling In the cyclones

- High grade casting fire doors

Environment friendly

- Most suitable tor renewable fuels

- Cyclones are provided wIth anti-abrasive filling for long Life

- High efficient furnace ensures complete combustion

- An efficient heat recovery unit

- Reduced power consumption

Operational Advantages

CBL HYPAC is designed to offer you the most efficient and hassle-free operations.

Apart from being the most economical option, its functioning is designed to increase the

effectiveness of the operations achieving economies of scale and generating higher returns.

- Multiple-fuel options making HYPAC an ideal investment

- Specially designed fluidized bed combustion furnace – well suited for burning fuels like rice husk, sawdust, groundnut shell, DOC (de-oiled cake), coal, briquettes, bagasse etc.

- Combination fuel options- e.g., oil/gas and solid fuel

- Quick fuel switching with minimum adjustments

- Centralized instrumentation and electrical control panel

- The option of step-less pressure control

- Automatic water level control and safety systems

- Easy ash handling with the option of continuous ash discharge